ACOUSTIC SIGNATURE Maximus neo silver

Brand

Acoustic Signature

Το εισαγωγικό πλατό απο την Acoustic signature

Calculating...

Ειδικά χαρακτηριστικά:

Αθόρυβο μοτέρ AC με εξωτερικό, εξαιρετικά σταθερό τροφοδοτικό πολλαπλής τάσης

Ενσωματωμένος ψηφιακός ελεγκτής κινητήρα Πρωτοποριακή τεχνολογία AVC επιπέδου 1 (Automatic Vibration Control)

Εξαιρετικά ακριβές, εξαιρετικά άκαμπτο και στιβαρό ρουλεμάν DTD® με άτρακτο επικαλυμμένο με διαμάντι (Dura Turn Diamond® Bearing)

Νέο και 30 % μεγαλύτερο πλαίσιο από κράμα αλουμινίου με μείωση του συντονισμού με πλατό αλουμινίου Ρύθμιση 3 σημείων με ειδικά πόδια που αποσβένονται με τζελ

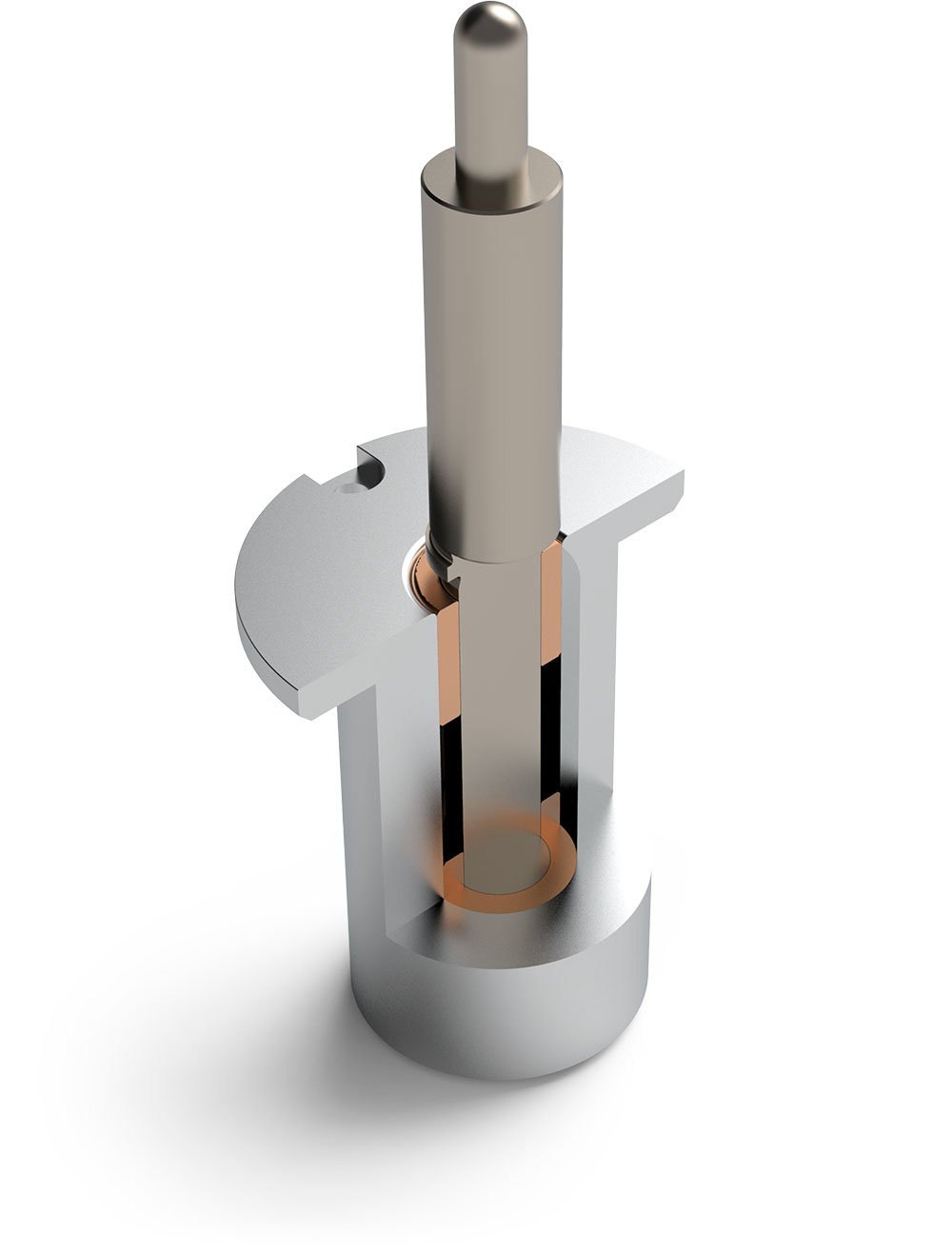

Acoustic Signature DTD® Bearing:

A class of its own!

The bearing is the heart of every turntable. Although the bearing design is of such great importance, its development – from the view of physics – is often characterized by imprecise to wrong approaches. Any conventional bearing that is confronted with a heavier platter is extremely sensitive in terms of handling. It also faces a mechanical challenge that is mainly to be found in the contact area of the thrust plate and bearing ball. In other words: the combination of the high platter weight and the very small ball surface causes an enormous pressure in the very small contact area, which simply pushes the lubricating oil away.

The result: too much friction, too much noise, too much vibration and rapid wear. Analogists seeking salvation in an ‘inverted bearing’ are misguided by a marketing trick: the main source of noise within a conventional bearing design is located at the pivot point of the platter axis and the thrust plate, about 4 inches away from the record. By inverting the bearing, this noise source is taken closer to the platter direct below the vinyl surface and thus into the activity area of the cartridge – definitely not a good idea. Moreover, this ‘reversal’ causes a veritable lubrication problem thanks to gravity: the oil is floating away at the contact surface.

When we introduced our Tidorfolon® Bearing in 1997, we immediately received enthusiastic feedback: made of a very innovative material combination, the Tidorfolon® Bearing was hard enough not to be affected by the high mass of the platter and soft enough to withstand even a ‘dropped’ plate without any damage. Another highlight: the material mix is able to absorb the oil like a sponge and release it when needed. In other words: the oil cannot be pushed away; the lubrication is always there when needed. Refill oil? Not necessary! Replenishment? Not necessary! Maintenance? Not necessary! Audiophiles and the specialist media worldwide have celebrated this extremely robust and low-noise bearing as a benchmark-setting innovation.

What’s the improvement of the DTD® Bearing: we succeeded in reducing the already imperceptible noise level caused by mechanical movement even further, thus making the famous background when listening to music even blacker. We achieved this by using newly developed sinter-bushes that can store three times the amount of lubricating oil. The design of the spindle was also put to the test. Our aim was to minimize its surface contact and the resulting noise. So, a vacuum-hardened stainless-steel spindle is grinded precisely and then subjected to an elaborate plasma coating. The result is a spindle with a diamond-like surface coating that competes with the hardest material on earth and reduces the friction coefficient by 60 percent!

The Dura Turn Diamond® Bearing is a super-rigid and virtually ‘indestructible’ bearing that creates the best possible conditions for absolute high-end sound and sets news benchmark in terms of maintenance, low noise and service life – backed by a 15-years warranty. The DTD® Bearing is manufactured for each turntable in the Acoustic Signature NEO series in an individual version adapted to the respective turntable.

Selected bearings

Bearings in the manufacture of Acoustic Signature before their assembly into the turntables. The bearings are made of a special material combination and are extremely sturdy and run revolutionary quiet.

Acoustic Signature AVC:

The Automatic Vibration Control

Every rotating motor generates vibrations. This inevitable force is transmitted to the chassis and platter and consequently has a negative effect on the sonic performance of a turntable. Accordingly, it is important to effectively reduce undesired vibrations or even better prevent them from occurring in the first place – so much for the theory.

Usually, this challenge is addressed by a focus on material selection, special measures for chassis and platter dampening, turntable setup and the design of the entire drive system including the motor selection. Due to budget and/or pricing policies, many manufacturers rarely consider a consistent combination of all the above measures. Apart from that, each developer will find out sooner or later that all those well-known approaches are limited – in terms of effectiveness. The concepts for vibration minimization only work up to a certain degree.

But we wouldn’t be Acoustic Signature if we didn’t go beyond the limits. In addition to our innovative Silencer and CLD (Constraint Layer Damping) technologies, we invented an additional milestone to reduce vibrations even further:

Acoustic Signature AVC – Automatic Vibration Control!

The vision of an Automatic Vibration Control was long born before the planning of our NEO series. During the development of our new turntable generation we found it was the right time to bring our ideas to life: The high-quality AC motors that drive our turntables are constructed with 2 coils and 24 poles. To make the coils rotate, they are fed with a sine wave and a 90° phase-shifted signal. Unfortunately all AC synchronous motors show production-related tolerances that prevent the poles and coils from being positioned one hundred percent correctly – a key reason for unwanted vibrations. In order to effectively minimize or even avoid these, all production tolerances must be compensated by other means.

This is where our AVC technology comes in: It is able to measure the resulting distortions in real time. Based on those measurements, AVC adjusts the phase shifts to the motor signals – also in real time and fully automatic! These digitally monitored corrective measures ensure a drastic reduction of the vibrations – an extra effective benefit for turntables driven by a multi-motor concept.

The sonic gain is so dramatic that we decided to equip all NEO series turntables with that breakthrough technology. Depending on the drive system and the number of motors used, our Automatic Vibration Control is implemented in three configuration stages, each with different intensity:

AVC Level 1, AVC Level 2 & AVC Level 3.

All stages – Level 3 stands for the highest efficiency – use different software and hardware. In addition, from Level 2 on, the motors are strictly selected and paired to maximize the effect.

Technical data

| AC-motors: | 1 (integrated) |

| Drive system: | RPM-regulated double belt drive with speed fine adjustment |

| AVC: | Level 1 |

| Speed range: | 33 1/3 RPM and 45 RPM |

| Power adapter: | External power supply (100 – 260 V AC / 24 V DC) (WxDxH: 6 x 12 x 5.5cm; 0.2 kg) |

| Control panel: | Integrated |

| Bearing: | High-precision Dura Turn Diamond® bearing |

| Tone arm compatibility: | 9 inch tonearms |

| Maximum number of tone arms: | 1 |

| Platter: | Aluminum anodized (Ø 300 x 34 mm / 5,8 kg) |

| Silencer: | – |

| Chassis: | 30 mm massive aluminum chassis |

| Feet: | 3 height-adjustable gel-damped aluminum feet |

| Dimensions (WxDxH): | 415 x 315 x 120 mm |

| Weight: | ca. 18 kg |

| Ταχύτητα: | 33, 45 |

|---|---|

| Μετάδοση: | Belt drive |

Validate your login